Description

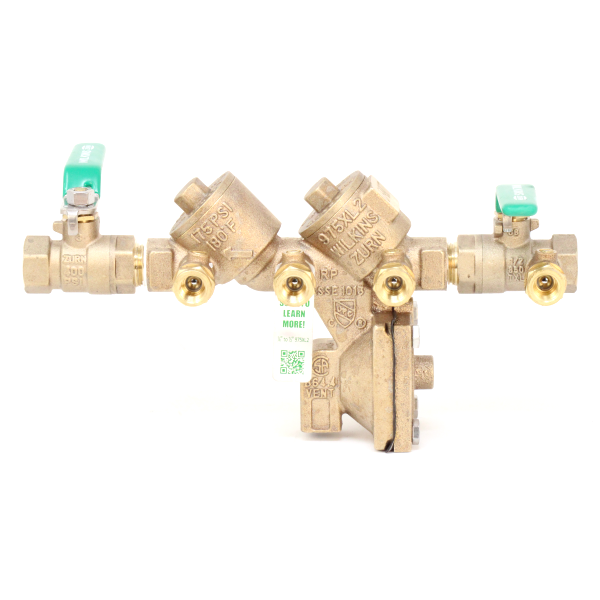

Zurn Wilkins 975XL2 Lead-Free RPZ Backflow Preventer Series, Reduced Pressure Type - Premium Water Protection Solution.

Product Overview:

The Zurn Wilkins 975XL2 Reduced Pressure Principle Backflow Preventer (RPZ) is a lead-free, high-performance water safety device designed to protect potable water systems from contamination caused by backsiphonage and backpressure. Featuring a compact wye-pattern design, this low-maintenance and installer-preferred RPZA valve offers seamless integration into various residential, commercial, and industrial applications where lead-free compliance is required.

Key Features & Benefits:

✅ Wye-Pattern Design – Reduces lay length, making installation and replacement easier

✅ Short Lay Length – Lowers labor costs for quick and efficient replacements

✅ Lead-Free Compliance – Meets NSF/ANSI 61 low-lead requirements for safe water applications

✅ Serviceable In-Line – Access check valves without removing the relief valve or entire unit

✅ Durable Construction – Built with low-lead cast bronze and corrosion-resistant materials

✅ Versatile Installation Options – Indoor installations can include an air gap adapter and monitor switch

✅ Certified & Compliant – Exceeds industry standards for backflow prevention

Available Sizes:

Application & Use Cases:

Designed for potable water systems, this RPZ backflow preventer is ideal for:

✔ Municipal water supplies

✔ Irrigation systems

✔ Fire protection systems

✔ Commercial and industrial plumbing systems

✔ Residential water safety applications

This low-lead model is required in areas where lead-free valves are mandated, ensuring compliance with local plumbing codes and health regulations.

Installation Guidelines:

📌 Complies with local plumbing codes for optimal performance

📌 Mounting height: 12” (305mm) to 30” (762mm) above a proper drain

📌 Ensure adequate clearance for testing and maintenance

📌 Must not be submerged to prevent damage or malfunction

💡 Pro Tip: Install in accordance with the Uniform Plumbing Code and manufacturer recommendations for maximum efficiency.

Technical Specifications:

| Max. Working Pressure: | 175 psi |

| Max. Working Temperature: | 180°F |

| Hydrostatic Test Pressure: | 350 psi |

| End Connections: | Threaded FNPT ANSI B1.20.1 |

| Lead-Free Compliant: | Yes! NSF 61 Certified |

🔧 Reliable performance in high-pressure water systems!

Industry Certifications & Compliance:

✔ ASSE® Listed 1013

✔ IAPMO® Listed

✔ CSA® Certified B64.4

✔ AWWA Compliant C511

✔ NSF/ANSI 61 Certified (0.25% MAX weighted average lead content)

✔ UL® Classified (without shut-off valves or with OS&Y valves)

✔ C-UL® Classified

✔ Approved by the Foundation for Cross-Connection Control & Hydraulic Research at USC

Premium Materials for Long-Lasting Performance:

| Main Valve Body: | Low Lead Cast Bronze (ASTM B 584) |

| Access Covers: | Low Lead Cast Bronze (ASTM B 584) |

| Fasteners: | Stainless Steel (300 Series) |

| Elastomers: | FDA-Approved Silicone & Buna Nitrile |

| Internals: | Delrin & Nylon (NSF Listed) |

| Polymers: | Noryl™ |

| Springs: | Stainless Steel (300 Series) |

| Ball Valve Handles: | Stainless Steel |

Why Choose the Zurn Wilkins 975XL2 RPZ?

✔ Superior Protection – Prevents water contamination from backflow hazards

✔ Quick & Easy Maintenance – Top-access check valves for in-line servicing

✔ Trusted by Professionals – Installer-preferred design for seamless integration

✔ Lead-Free Compliance – Safe for use in potable water systems

✔ Industry-Leading Certifications – Exceeds standards for backflow prevention

Frequently Asked Questions (FAQs):

❓ What makes this backflow preventer lead-free?

✔ It meets NSF/ANSI 61 certification, ensuring a low lead content below 0.25% for potable water safety.

❓ Is this suitable for residential and commercial use?

✔ Yes! It is designed for both residential and commercial applications, including municipal water systems, irrigation, and fire protection.

❓ How often should I service this backflow preventer?

✔ Annual testing and maintenance are recommended to ensure compliance and functionality.

❓ Can I install this unit indoors?

✔ Yes, but an air gap adapter and monitor switch may be required for indoor installations.

❓ Does it comply with plumbing codes?

✔ Absolutely! It is ASSE® 1013, IAPMO®, CSA®, AWWA, NSF/ANSI 61, and UL® classified.

❓ Is this a new valve?

✔ Yes, this is a brand new, never installed valve.

❓ Is warranty included?

✔ Yes, standard manufacturer warranties apply on all products.

🛒 Get the Zurn Wilkins 975XL2 RPZ Backflow Preventer Today for Reliable & Lead-Free Water Protection! 🚰

Estimate shipping

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.