Description

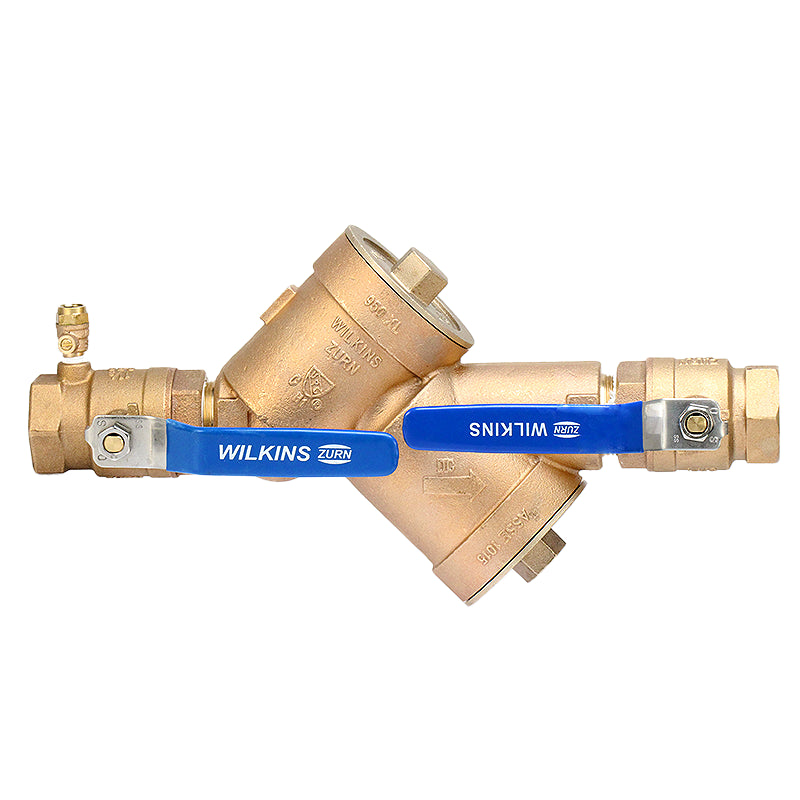

Zurn Wilkins 112-950XL 1-1/2" DCVA Double Check Backflow Preventer Valve - Reliable Backflow Protection for Low-Hazard Applications.

Overview:

The Zurn Wilkins 112-950XL 1.5 " Double Check Valve Assembly (DCVA) is a high-performance backflow preventer designed to safeguard non-potable water systems from contamination. Engineered with a wye pattern bronze body, this double check valve is ideal for low-hazard applications, protecting against backsiphonage and backpressure without compromising water flow efficiency.

Available Sizes:

Key Features & Benefits:

✅ Compact Wye Pattern Design – Short lay length for easy installation in confined spaces.

✅ Durable Bronze Construction – ASTM B 584 cast bronze body ensures longevity and corrosion resistance.

✅ Replaceable Components – Features NSF-listed Noryl® seat rings and silicone seal rings for extended product life.

✅ Non-Health Hazard Applications – Designed for low-risk water systems where contaminants pose no significant health threats.

✅ Easy Maintenance – Accessible first and second checks allow for maintenance without removing the valve from the pipeline.

✅ Full Port Ball Valves Included – Ensuring optimal water flow and system efficiency.

Product Specifications:

| Max. Working Pressure: | 175 PSI |

| Max. Operating Temperature: | 180°F |

| Hydrostatic Test Pressure: | 350 PSI |

| End Connections: | Threaded ANSI B1.20.1 |

| Spring-Loaded Stainless Steel Checks | 300 series stainless steel internals for durability. |

| Elastomers: | FDA-approved silicone and Buna Nitrile for superior sealing. |

| Lead-Free NSF61 Compliant | No |

🔧 Reliable performance in high-pressure water systems!

Application & Compliance:

The Zurn Wilkins 950XL DCVA is engineered for commercial, industrial, and municipal applications, ensuring compliance with local regulations. This ASSE 1015-listed backflow preventer is installed on water lines to prevent contaminated water from entering the potable supply due to backsiphonage or backpressure.

🔹 Approvals & Certifications:

✔ ASSE® 1015 Listed (Vertical 3/4", 1-1/2", 2")

✔ IAPMO® Listed (Vertical 1-1/2", 2")

✔ CSA® Listed (Vertical 3/4", 1-1/2", 2")

✔ AWWA C510 Compliant

✔ UL® & C-UL® Classified (Less shut-off valves)

✔ University of Southern California (USC) Approved (Vertical 3/4")

✔ City of Los Angeles Approved (Vertical 1-1/2", 2")

✔ NYC MEA 426-89-M VOL 3 Approved

Installation Guidelines:

For optimal performance, this double check valve assembly must be installed per local plumbing codes and the Uniform Plumbing Code. Recommended installation parameters include:

📌 Complies with local plumbing codes for optimal performance

📌 Mounting height: 12” (305mm) to 30” (762mm) above a proper drain

📌 Ensure adequate clearance for testing and maintenance

📌 Must not be submerged to prevent damage or malfunction

💡 Pro Tip: Install in accordance with the Uniform Plumbing Code and manufacturer recommendations for maximum efficiency.

Why Choose the Zurn Wilkins 950XL DCVA?

✔ Trusted Brand: Zurn Wilkins is a recognized leader in backflow prevention technology.

✔ High-Quality Materials: Bronze, stainless steel, and NSF-listed components for maximum durability.

✔ Reliable Backflow Protection: Prevents the risk of polluted water entering potable systems.

✔ Versatile Applications: Ideal for commercial buildings, irrigation systems, and fire protection lines.

FAQs

❓ What is a double check valve backflow preventer?

✔ DCVA (Double Check Valve Assembly) consists of two check valves that prevent the reversal of water flow, stopping potential contaminants from entering the clean water supply.

❓ Can this valve be installed vertically?

✔ Yes, the Zurn Wilkins 950XL can be installed both horizontally and vertically, depending on the approved size variations.

❓ How often does this backflow preventer need maintenance?

✔ Routine annual testing is recommended, per local plumbing codes, to ensure continued compliance and proper function.

❓ Does this come with ball valves?

✔ Yes, this model includes full-port ball valves for optimal water flow and easy shutoff.

❓ What’s the difference between a DCVA and an RPZ backflow preventer?

✔ DCVA protects against low-hazard applications (e.g., irrigation, industrial water systems), while an RPZ (Reduced Pressure Zone) assembly is required for high-hazard applications involving harmful contaminants.

❓ Is the 950XL series lead-free?

✔ NO. The 950XL series is not considered a lead-free device. See the 950XLT2, or 350XL series for the lead-free version of a 950XL.

Order the Zurn Wilkins 112-950XL DCVA Today!

Get superior backflow prevention with the Zurn Wilkins 950XL. Available in multiple sizes for various applications. Ensure compliance, safety, and efficiency in your water system today!

🔹 Need help choosing the right size? Contact us for expert recommendations.

🛒 Get the Zurn Wilkins 112-950XL DCVA Backflow Preventer Today for Reliable Water Protection! 🚰

Estimate shipping

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.