Phone & Email Support

1-844-597-3070 * info@masterbuildermercantile.com

Free Ground Shipping

Free shipping on orders over $125.00 USD. Express available.

Satisfied or Refunded

Refund Available Within 30-Days of Purchase

Secure Information

Secure and Encrypted Payments.

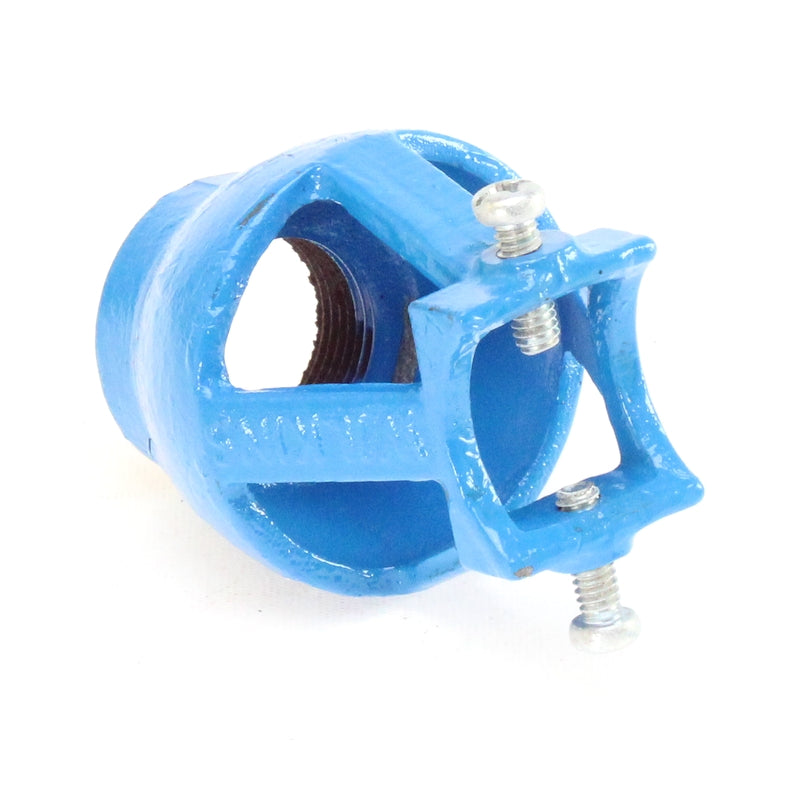

Preventores de reflujo

399 productos

Mostrando 1 - 24 de 399 productos

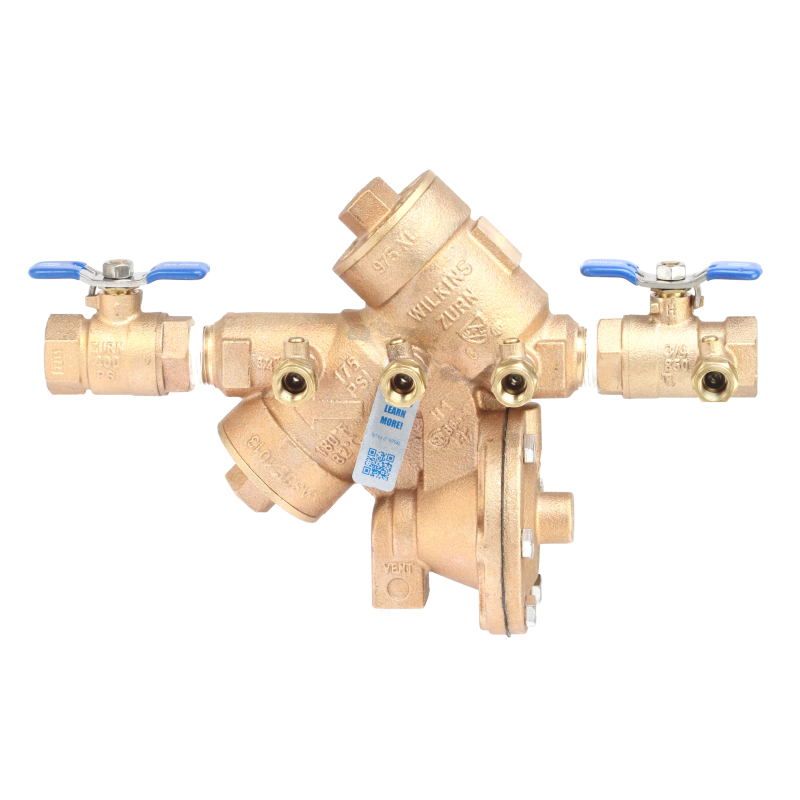

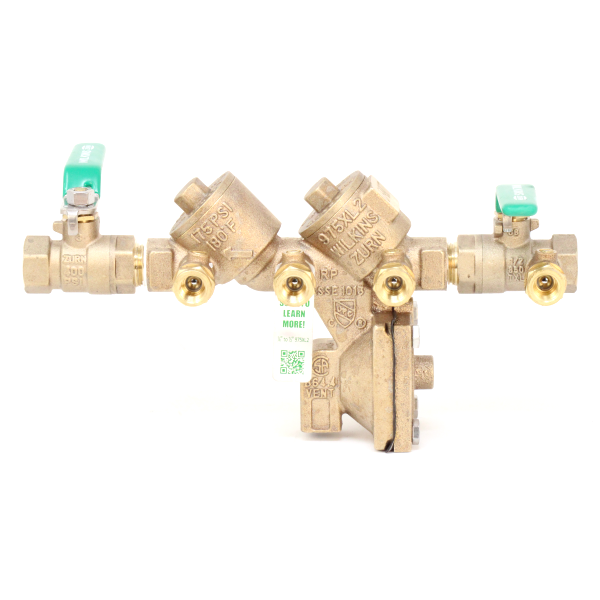

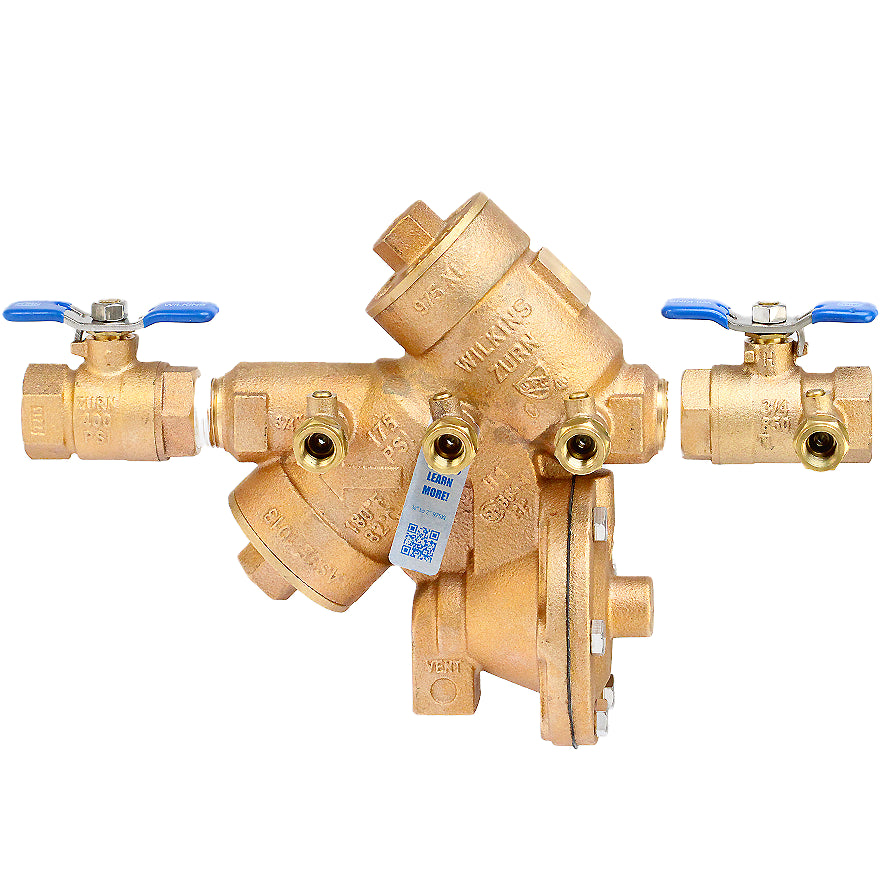

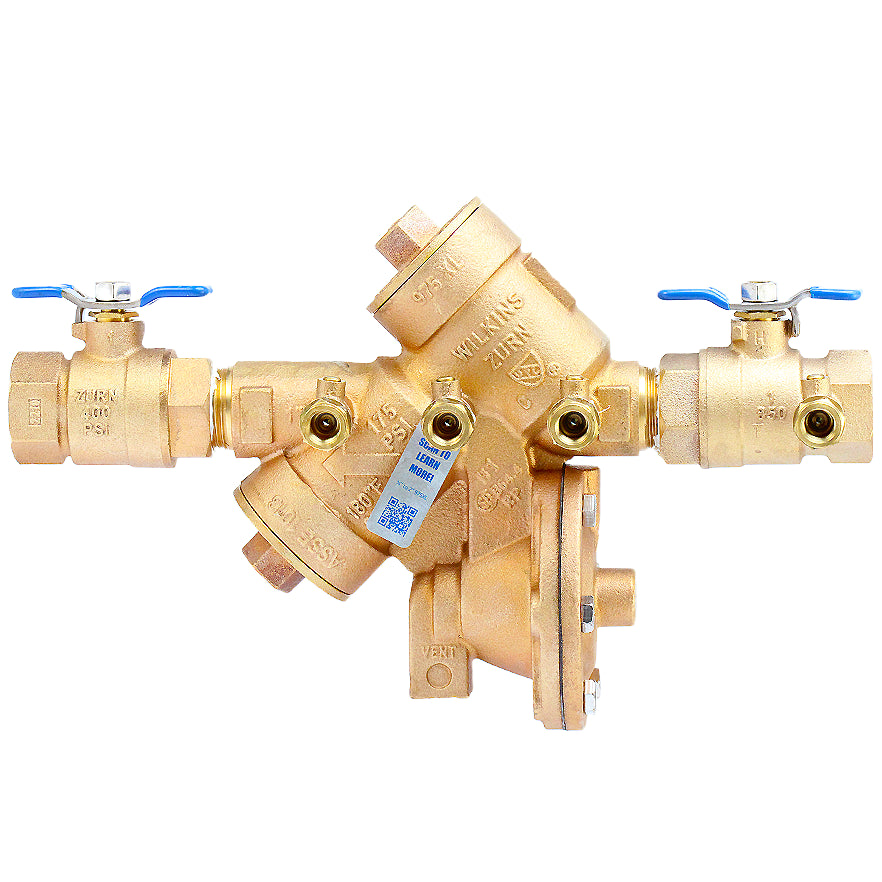

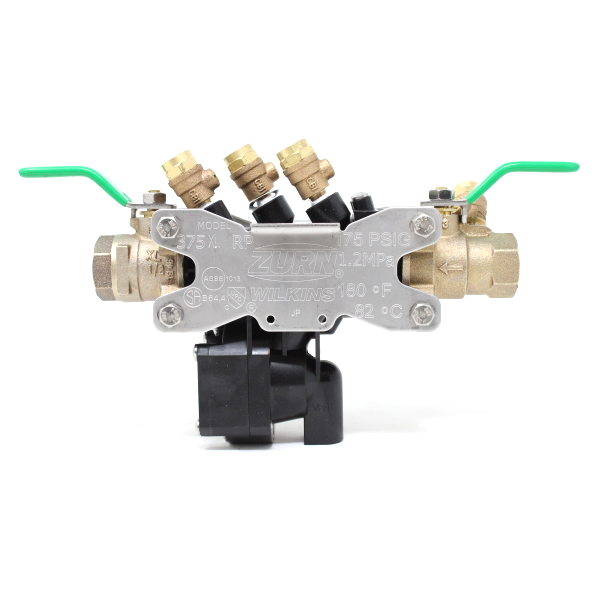

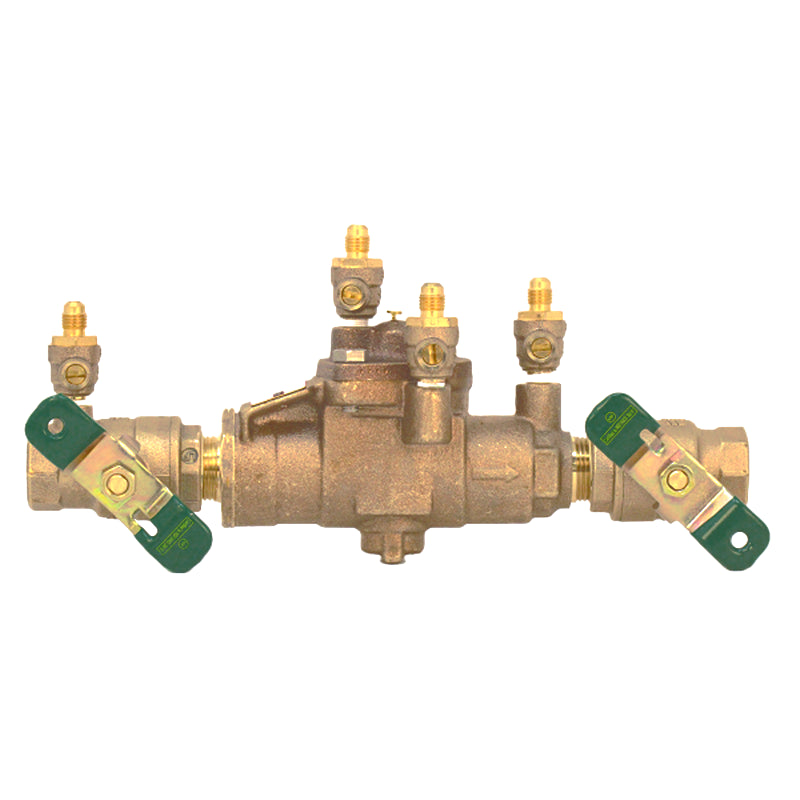

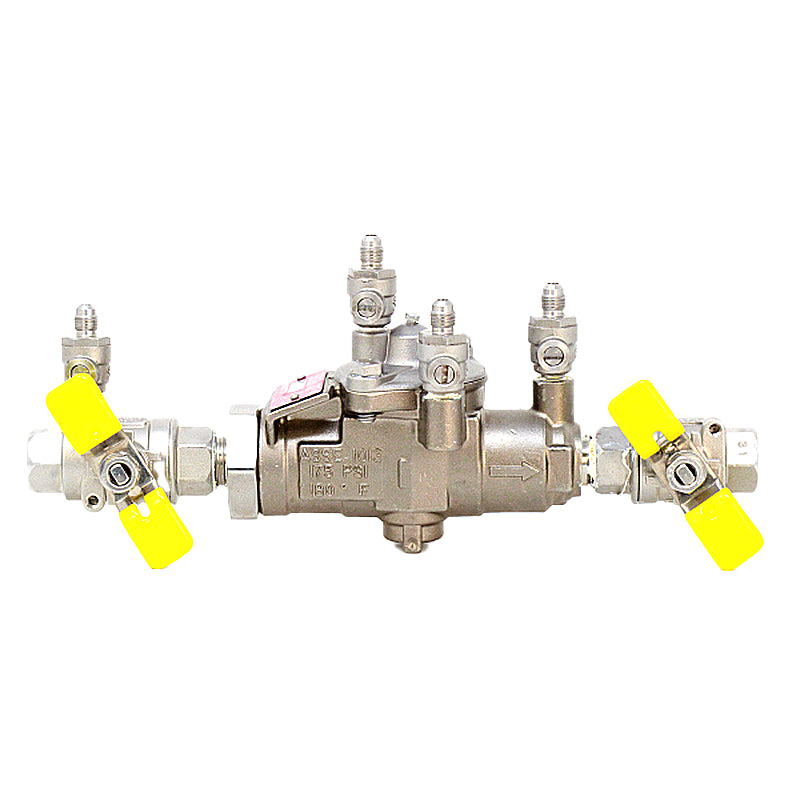

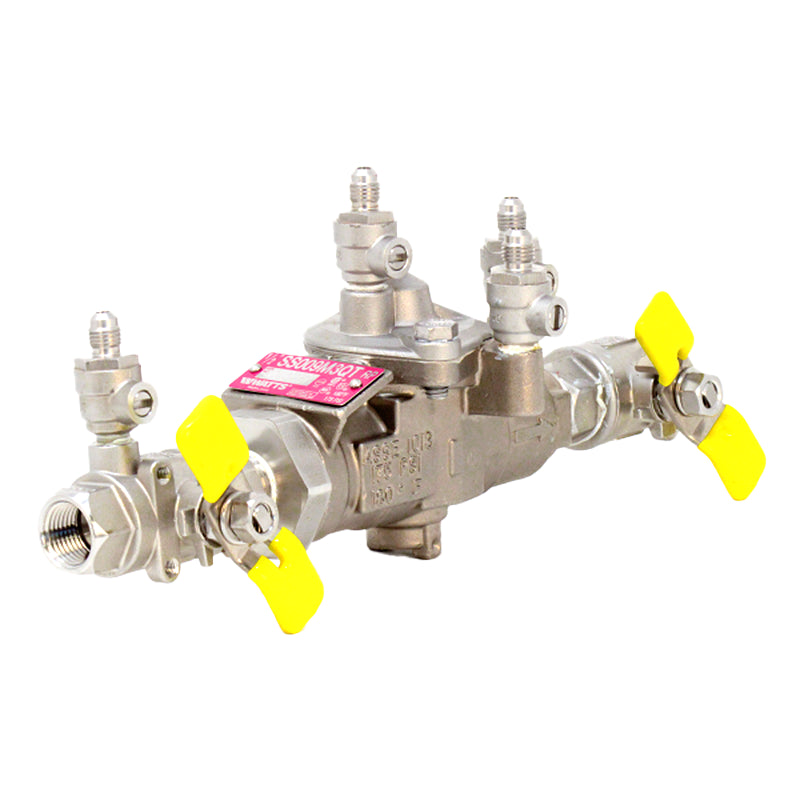

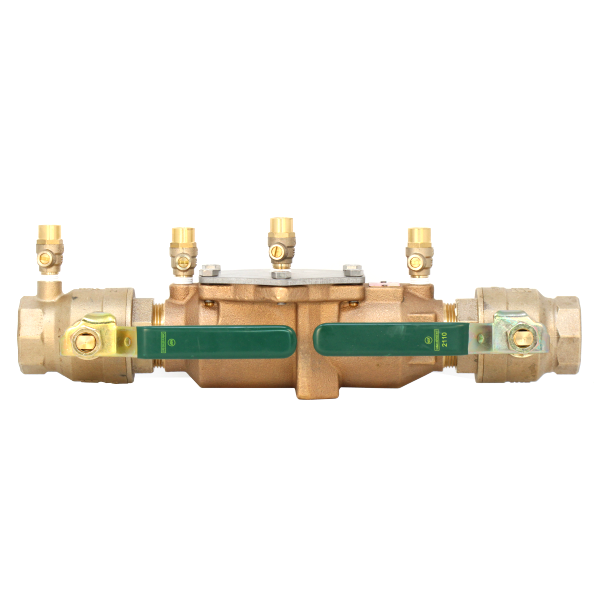

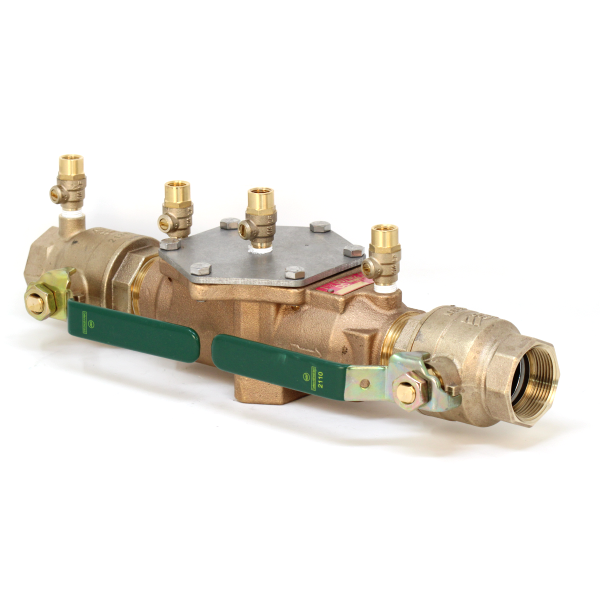

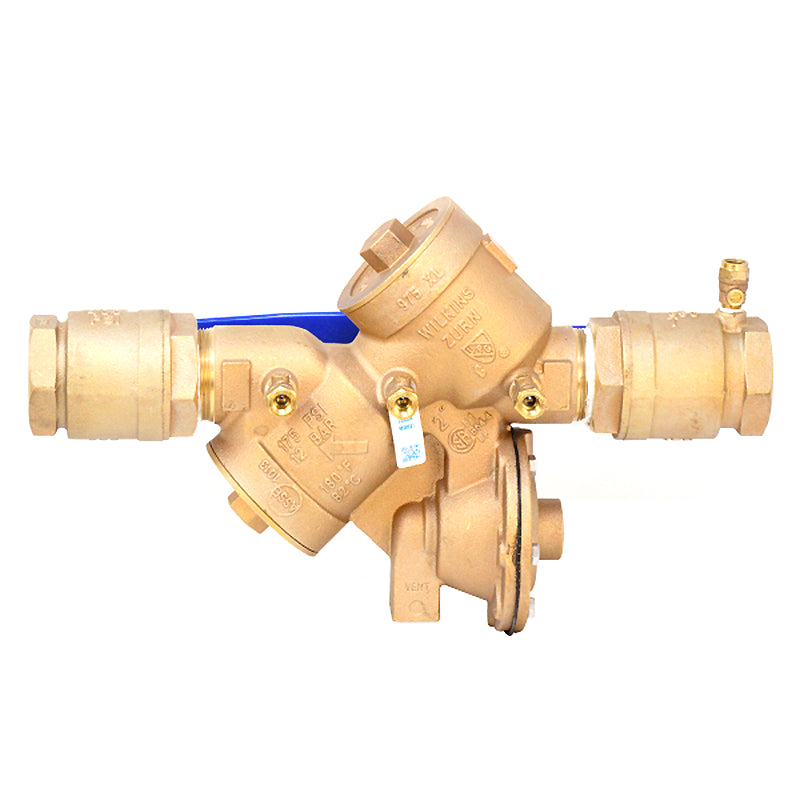

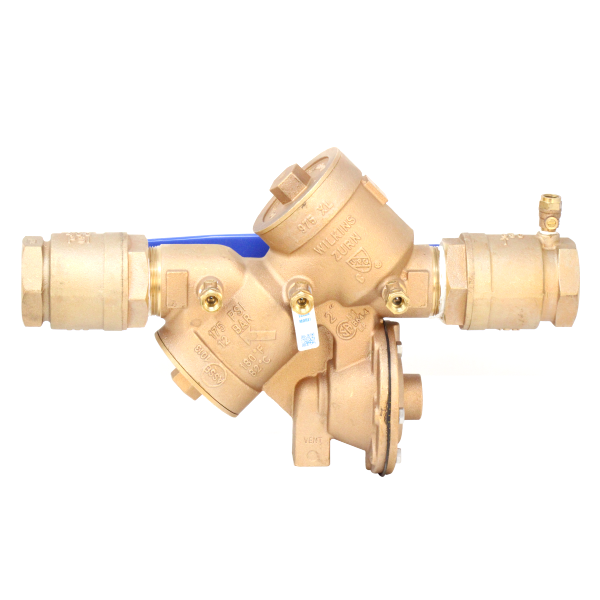

Backflow Preventer Valve For Sale

If your looking to buy a Backflow Preventer or DCVA to safeguard your water or plumbing system, you've come to the right spot! Welcome to our collection of Backflow Preventer Valves where you can shop our wide selection of plumbing backflow preventer devices from top brands such as Wilkins, Watts, and more. We offer the best prices and fastest shipping so you can protect your sprinkler, sewer, or irrigation system in a timely matter. Protect your water supply whether it be residential or commercial with these leading backflow valve products. Buy RPZ Valve here.

|

|

|

Zurn Backflow Preventer |

Watts Backflow Preventer |

Apollo BackFlow |

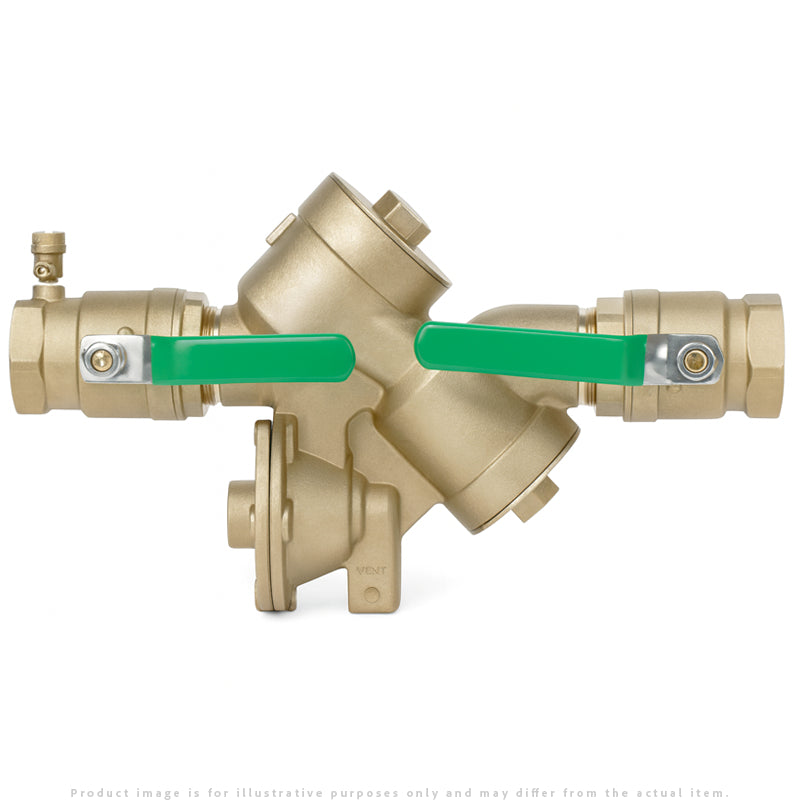

What is a Backflow Preventer?

A backflow preventer is a device designed to protect potable water supplies from contamination or pollution due to backflow. Backflow occurs when the flow of water reverses direction, potentially allowing contaminants to enter the clean water supply. This reversal can be caused by changes in water pressure, such as during a water main break or heavy water usage.

Backflow preventers are commonly used in residential, commercial, and industrial plumbing systems to ensure that drinking water remains safe. They are particularly important in systems where there is a risk of cross-connection between clean water and potential sources of contamination, such as irrigation systems, fire sprinklers, or industrial processes.

Common Acronyms for Backflow Preventers

- RPZ (Reduced Pressure Zone): A specific type of backflow preventer with two check valves and a relief valve to handle high-risk scenarios.

- DCVA (Double Check Valve Assembly): A backflow preventer with two check valves for moderate-risk situations.

- PVB (Pressure Vacuum Breaker): A device used to prevent back-siphonage, ideal for irrigation systems.

- AVB (Atmospheric Vacuum Breaker): A simpler back-siphonage prevention device that relies on air pressure.

- RPBA (Reduced Pressure Backflow Assembly): Another term for RPZ, focusing on high protection levels against contamination.

How Does It Work?

The backflow preventer operates as a one-way valve that allows water to flow in only one direction. If pressure drops and water attempts to flow backward, the device shuts off the reverse flow to block contamination.

Why Are Backflow Preventers Important?

- Protect Drinking Water: They safeguard potable water supplies from harmful substances.

- Ensure Compliance: Many building codes and regulations require backflow preventers in certain applications.

- Peace of Mind: They help maintain water quality for your home or business.

Backflow preventers are an essential part of modern plumbing systems, ensuring the safety and reliability of your water supply.

Key Applications of Backflow Preventers

Backflow preventers are widely used to safeguard potable water in the following scenarios:

- Irrigation Systems: Prevents fertilizers, pesticides, or stagnant water from contaminating the water supply.

- Fire Suppression Systems: Stops stagnant water in fire sprinkler systems from flowing back into the drinking water.

- Commercial and Industrial Use: Ensures no cross-contamination occurs in industries handling hazardous chemicals.

-

Residential Plumbing: Protects home water supplies when connected to external sources like garden hoses or outdoor fixtures.

Understanding Backsiphonage and Backpressure

- Backsiphonage: Occurs when a negative pressure in the water supply system causes contaminants to be drawn into the potable water. This can happen due to water main breaks or heavy water usage.

- Backpressure: Happens when downstream pressure exceeds the supply pressure, pushing water (and potential contaminants) back into the clean water system. This is common in systems with boilers or elevated tanks.

Maintenance and Backflow Testing

Backflow preventers require regular maintenance and testing to ensure they operate efficiently. Many local regulations mandate annual testing by certified professionals, often using specialized backflow testing kits. Regular inspections help:

- Identify wear and tear or malfunctions.

- Ensure compliance with safety standards and regulations.

- Prolong the device's life and reliability.

Material and Construction of Backflow Preventers

Backflow preventers are typically constructed using durable materials such as:

- Bronze or Brass: For corrosion resistance and longevity.

- Stainless Steel: Offers additional durability for high-pressure or hazardous applications.

These materials ensure reliability in both residential and commercial environments.

Choosing the Right Backflow Preventer

The selection of a backflow preventer depends on the following factors:

- Type of Cross-Connection: Whether the risk involves backpressure or back-siphonage.

- Level of Hazard: Low, medium, or high contamination risks.

- System Requirements: Flow rate, pressure, and connection types.

Examples include Double Check Valve Assemblies (DCVA) for moderate-risk applications and Reduced Pressure Zone (RPZ) devices for high-risk environments.