Description

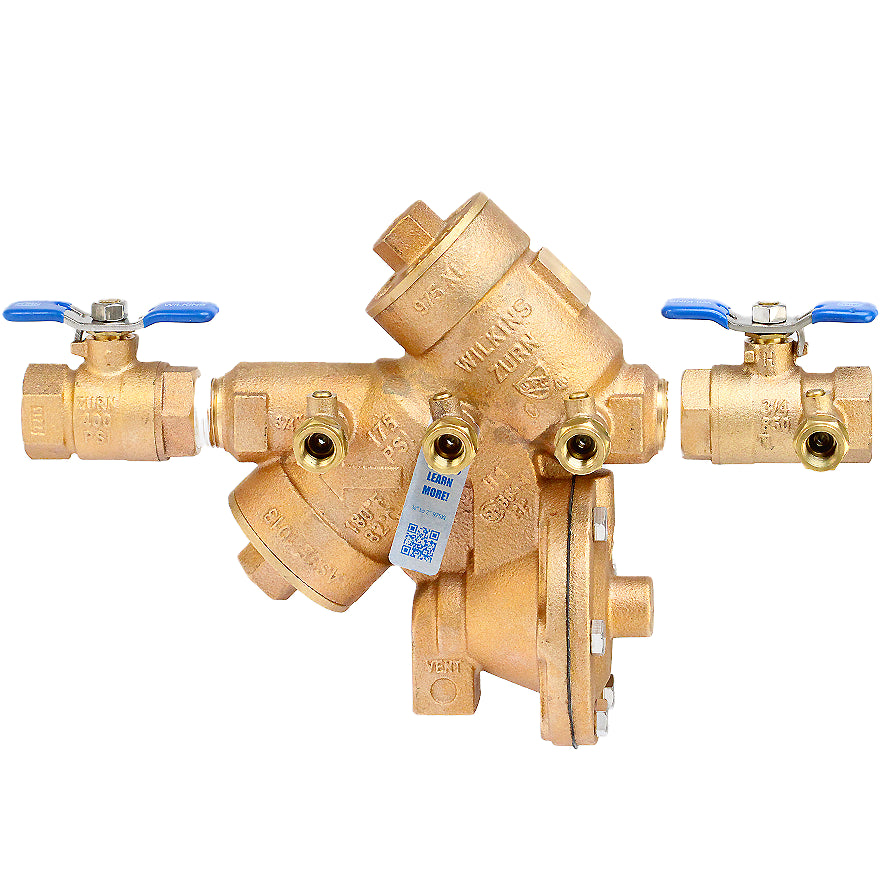

Zurn Wilkins 975XL 3/4" RPZ Reduced Pressure Backflow Preventer - High-Performance Water Protection Valve.

Overview:

The Zurn Wilkins 34-975XL 0.75" Reduced Pressure Principle Backflow Preventer is engineered to safeguard potable water supplies from high-hazard contamination due to backsiphonage and backpressure. Its wye-pattern bronze body ensures easy access for maintenance, reducing downtime and service costs. Built with corrosion-resistant internals, this assembly is designed for long-term durability and reliability in non-potable water applications.

Zurn Wilkins 34-975XL RPZ Backflow Features & Benefits:

✅ Premium Bronze Body – Corrosion-resistant for enhanced longevity

✅ Top Access Check Valves – Facilitates quick repairs in compact spaces

✅ Replaceable Check & Relief Valve Seats – Simplifies servicing and extends product life

✅ Compact & Versatile Design – Ideal for a wide range of applications

✅ Serviceable In-Line – Reduces labor costs and minimizes system downtime

✅ Wye-Pattern Design – Lowers installation time and expenses

Available Sizes:

Applications:

Designed for residential, commercial, and industrial water systems, the Zurn Wilkins 975XL prevents contaminated water from entering clean water supplies. It is an ideal choice for irrigation, fire protection systems, and municipal water supply lines where a potential health hazard may exist.

Meets or Exceeds Industry Standards:

✔ ASSE® 1013 Listed

✔ IAPMO® Certified

✔ CSA® B64.4 Compliant

✔ AWWA Approved

✔ Certified by the Foundation for Cross-Connection Control & Hydraulic Research (USC)

Materials:

- Main Valve Body: Cast bronze ASTM B 584 \

- Access Covers: Cast bronze ASTM B 584

- Internals: Stainless steel, 300 Series Elastomers Silicone (FDA approved) Buna nitrile (FDA approved)

- Polymers: Noryl™, NSF Listed

- Springs: Stainless steel, 300 series

Features:

- Sizes: 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", 2"

- Maximum Working Water Pressure: 175 psi

- Maximum Working Water Temperature: 180° F

- Threaded connections (FNPT): ANSI B1.20.1

- Hydrostatic Test Pressure: 350 PSI

- Relief Valve Discharge Port:

- 1/4” - 1/2” - 0.38 sq. in.

Installation Guidelines:

📌 Follow local plumbing codes for compliance and proper operation

📌 Installation Height: 12" (305mm) to 30" (762mm) above an adequate drain

📌 Ensure side clearance for testing and maintenance

📌 Prevent submersion or water damage from relief valve discharge

💡 Tip: Always install in accordance with the latest Uniform Plumbing Code and manufacturer instructions.

Why Choose the Zurn Wilkins 975XL?

✔ Industry-Leading Protection – Meets stringent cross-connection control standards

✔ Ease of Maintenance – Quick access for debris removal & servicing

✔ Time & Cost Efficiency – Wye-pattern design for simple installation

✔ Proven Reliability – Trusted by installers and water professionals worldwide

Frequently Asked Questions (FAQs):

❓ What is the purpose of a Reduced Pressure Principle Backflow Preventer?

✔ It protects potable water from contamination by preventing the reverse flow of non-potable water due to backpressure or backsiphonage.

❓ Where can this be installed?

✔ It is suitable for residential, commercial, and municipal applications, including irrigation systems, fire protection, and industrial facilities.

❓ How often does it need maintenance?

✔ Regular annual testing and maintenance are recommended to ensure optimal performance and compliance with local codes.

❓ Does this meet industry compliance standards?

✔ Yes! It is ASSE® 1013, IAPMO®, CSA®, AWWA, and USC Foundation for Cross-Connection Control certified.

Media:

Estimate shipping

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.